Quality

Guaranteed Quality

Quality control is at the heart of everything we do. We pay close attention to every step of the process, from sourcing the raw materials to the final pressure test.

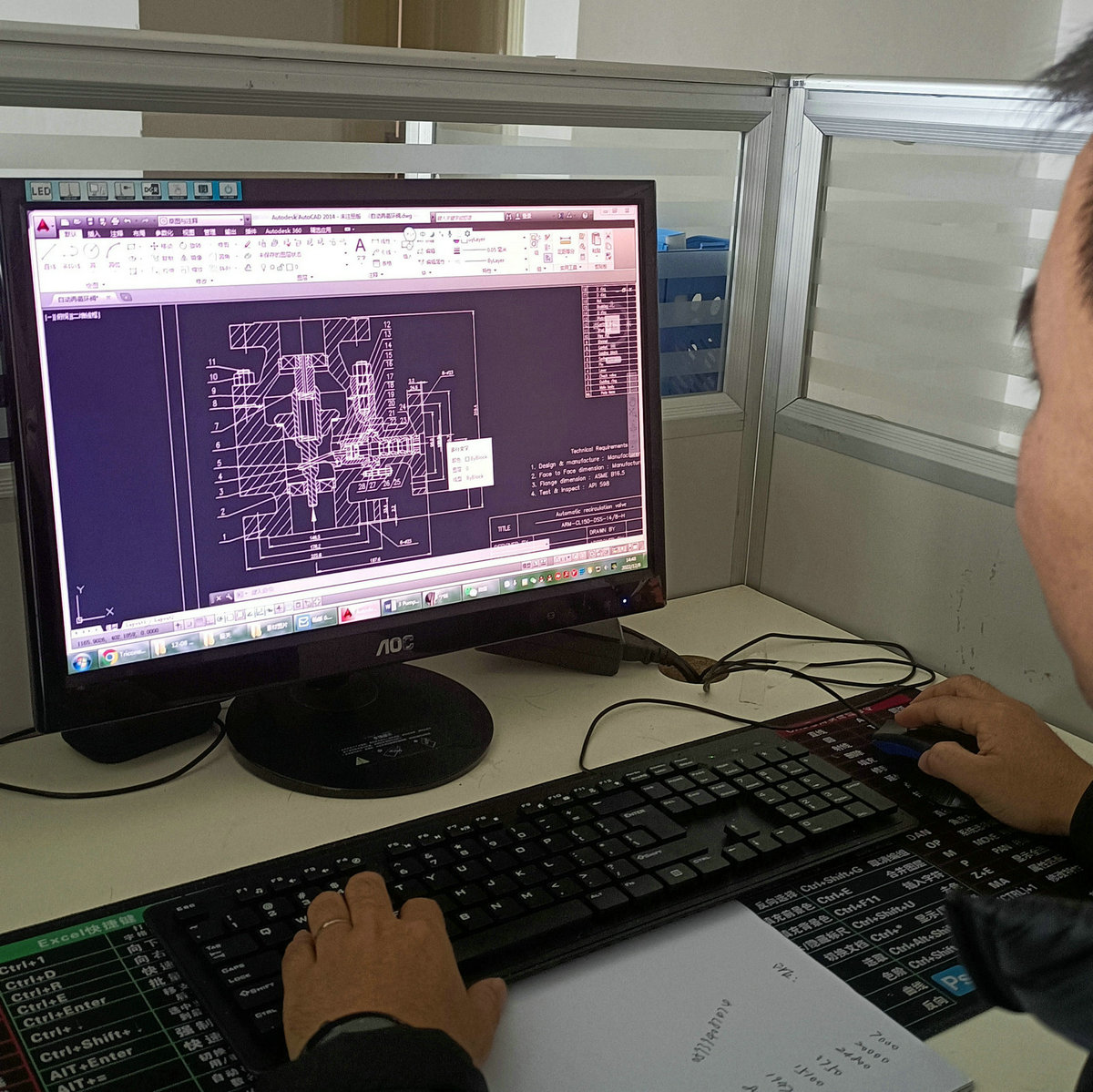

Design

We tailor each valve to meet our customers’ specific requirements. We use the latest technology to calculate and design the disc size and curve, as well as the spring back force required by the spring.

Raw material

Whether it is castings or forgings, we source only the best materials from top suppliers in China, so you can trust the quality and traceability of the materials used in your valve.

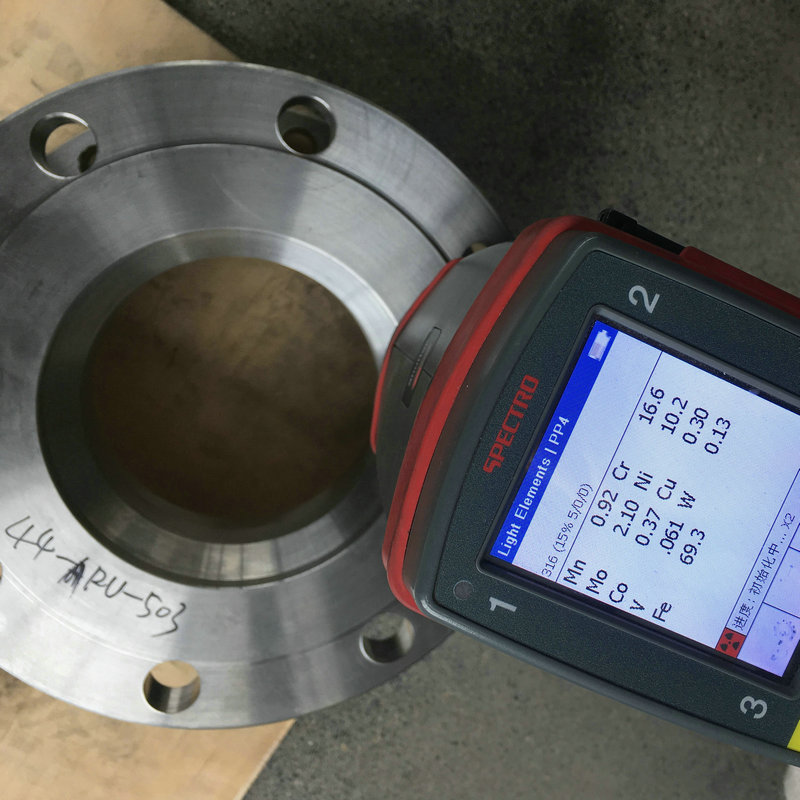

PMI (Positive Material Identification)

All raw materials undergo a thorough inspection process, including PMI (Positive Material Identification), to ensure their mechanical and chemical properties are up to standard.

Fabrication

90% of the valve body is fabricated using state-of-the-art CNC machines, ensuring precision and accuracy with a tolerance of only ±2mm.

Component

Over 95% of the component parts are also processed with high-precision CNC tools, resulting in a smooth surface finish with a surface roughness of only Ra1.6.

Assemble

Assembly is a crucial step in the process, and our experienced workers take great care in ensuring each valve is assembled to the highest standard. With each of them having over three years of experience, they know the key points to look out for to ensure a successful outcome.

Pressure test

To ensure the quality and reliability of our valves, we pressure test each and every one before delivery. You can trust that your valve will perform to the best of its ability.

Painting

We offer both factory standard painting and custom paint options to meet your needs.

Package

Our packaging is made of sturdy, Sea Worthy Plywood Cases, which protect the valve during transportation and ensure it arrives at its destination in pristine condition.