Choke Valve

Precision Control, Lasting Durability, Designed for Severe Service

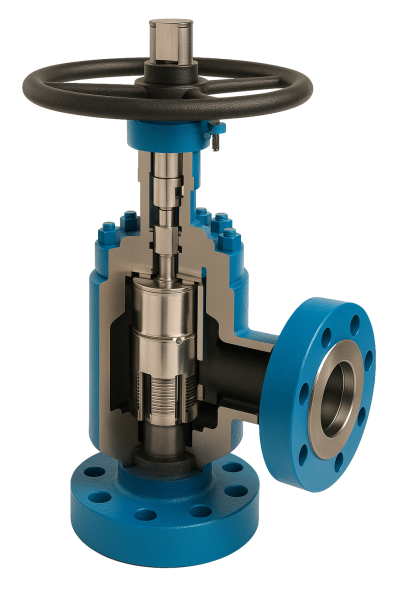

Angle Choke Valve

The Kamboowell Series Angle Choke Valve is engineered for precise flow regulation in severe service applications, offering exceptional durability and control under high pressure drops and erosive conditions.

Technical Specifications

- Size:1~12''/DN25~DN300

- Pressure Rating:ASME Class 150 to 2500 / API 6A 2000 to 15000 PSI

- End Connections:Flanged (RF, RTJ), Butt Weld (BW)

- Body Type:Forge

- Body Materials:ASTM A105, A350 LF2, A182 F316/F316L, Duplex, Super Duplex, Inconel,Customized material

- Trim Materials:316SS, 17-4PH, Stellite 6,

- Trim Characteristic:Equal Percentage, Linear, Quick Opening

- Actuation:Manual, Pneumatic Actuator, Electric Actuator

- Temperature Range:-46°C to +450°C (-50°F to +842°F)

Product Overview

The Kamboowell Series Angle Choke Valve is a heavy-duty, reliable solution for critical flow control in oil & gas production, refining, chemical processing, and power generation. Its angle body design is particularly suited for handling high-pressure drops and flashing services, minimizing body erosion and extending operational life. The valve’s internals are designed for optimal flow geometry, reducing turbulence and noise.

We offer a range of materials and trim configurations to meet specific process requirements, ensuring compatibility with various corrosive and erosive media. Each valve undergoes rigorous testing to guarantee performance and safety.

Typical Applications

- Oil & Gas Wellhead Production Chokes

- Gas Lift Injection Control

- Water Injection Flow Control

- Separation & Processing Skids

- Pipeline Pressure Regulation

- Refinery & Petrochemical Critical Process Control

- Geothermal Steam Control

- High-Pressure Letdown Stations

Our Unique design

Our choke valves are not just standard products; they are engineered solutions. Here’s why Kamboowell stands out:

Advanced Multi-Stage Trim Design

Our optional multi-stage trim breaks down high pressure drops into smaller, manageable stages. This innovative design effectively prevents cavitation, reduces noise, and minimizes erosion, drastically extending the valve’s operational life.

Proprietary Material Hardening

We utilize specialized heat treatment and surface hardening processes for our valve trims. This results in superior hardness and toughness, providing unmatched resistance to wear and erosion from abrasive fluids and high-velocity flow.

Optimized Flow Path Geometry

Through extensive Computational Fluid Dynamics (CFD) analysis, we’ve designed the internal flow path to be as smooth as possible. This minimizes turbulence and pressure loss, ensuring stable control and reducing wear on the valve body and downstream piping.

Ready to Enhance Your Process Control?

Contact our valve experts today to discuss your specific application requirements. We’ll provide a detailed quote and technical recommendation tailored to your needs.