What's Automatic Recirculation Valve?

Automatic Recirculation Valve, also be called pump protection valve, minimum flow valve, is a special valve specially used to protect the circulating pump from cavitation damage.

Why Automatic Recirculation Valve come out?

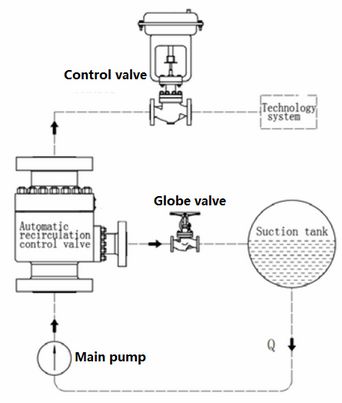

To prevent Cavitation, the designer need to design a system to ensure the minimum flow of the pump. When pump main flow rate is lower than the ideal minimum flow rate, this system will work to guarantee the fixed minimum flow rate of the pump all the time. This system is called “Recirculation System”.

Three Recirculation Systems to prevent Cavitation

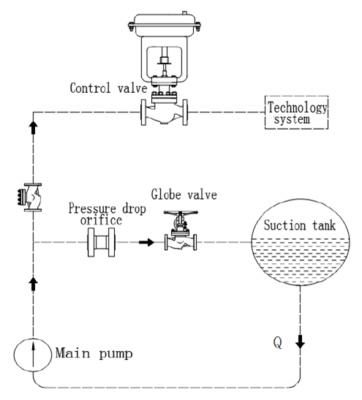

1.Continuous Recirculation System (Orifice Plate)

The continuous recirculation system is mainly consist of pressure drop orifice and globe valve. After setting the minimum flow rate, continuous recirculation system reflux flow to the tank through the orifice plate directly.

Disadvantage:

Although continuous minimum cycle flow can protect the pump very well, the pump must provide greater output power to ensure the pipeline flow, thus, more additional energy will be wasted.

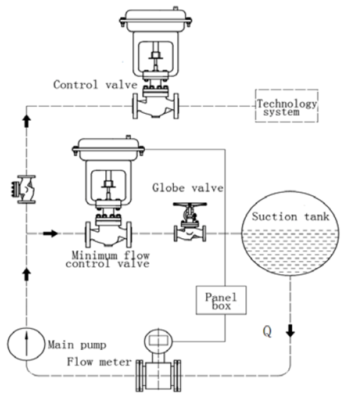

2.Controlled Recirculation System (Minimum Flow Control Valve

Control recirculation system is consisted by check valve, flow meter, minimum flow control valve and panel box. It provide minimum flow protection, when main pipeline flow is smaller than minimum flow of pump, no extra energy lost.

Disadvantage:

This system is complex, maintenance cost is higher because more control component and installation.

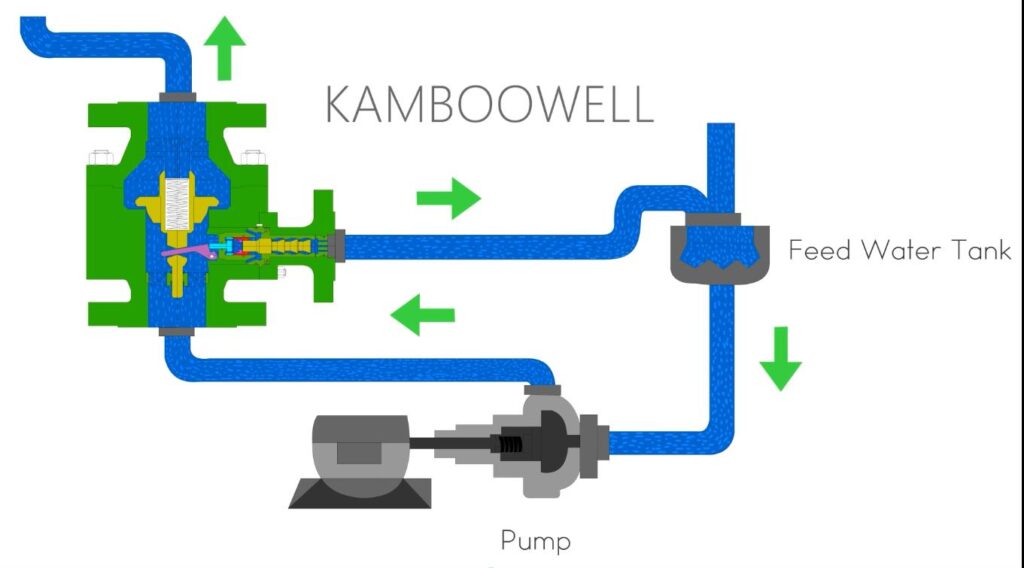

3. Automatic Recycle Valve System (Auto Recirculation Valve)

Advantages:

- Because there is no requirement of electricity, so no explosion-proof requirements in the chemical industry.

- Self-operated of flow control,no need of electrical control system and no additional energy.

- Remove the inlet and outlet flow meter and the minimum flow valve, without access to the DCS system, Without any additional components, only a mechanical structure of the valve will protect the pump, lower failure rate.

- In the product procurement, installation and commissioning at early step, as well as the maintenance at latter step, has significant cost advantage, the overall cost is lower 50% than the traditional control valve system.

- Simplify the complex system structure, reducing the space occupied by the equipment greatly.

Because of advantage of Automatic Recycle Valve System,so Automatic recirculation valve is increasingly favored by customers.

Where does Automatic Recirculation valve application on?

Automatic Recirculation valve be application on below:

- Chemical industry

- Petrochemical industry

- Steel factory

- Fire protection system

- Traditional power plant

- Paper-making industry

- Shipment/shipping

- Environmental protection industry

How does Automatic Recirculation Valve work?

Although the design structure of the automatic recirculation valve is very complicated, the working principle is very simple.

The working principle of the automatic recirculation valve can be summarized in one sentence: the valve disc is opened and closed by the combined action of the force generated by the main flow and the spring force, while the bypass is opened and closed by means of a connecting rod component.

- Normal situation: the main flow Q(m) is bigger than the minimum flow Q (min), the force of the main flow on the disc is bigger than the spring force, the main flow disc is fully opened and is at the highest position, and the bypass is closed.

- When P1 decreases↓, the main flow Q(m) decreases ↓, and the force of the main flow on the valve disc drops too. The valve disc moves downward under the action of the spring force, so the main flow disc is slightly closed, and the bypass will be slightly opened.

- If P1 continues to decrease ↓, the main flow Q(m) continues to decrease ↓, and the force of the main flow on the disc also decreases ↓ accordingly. The disc of the main flow continues to move downward under the force of the spring. When Q(m)<Q(min), The force of the spring is bigger than the force of the main flow on the disc, and the main flow Q(m)=0. At this time, the bypass will be fully opened to realize the circulation of the flow and protect the pump from cavitation.

- When P1 increases ↑, the main flow Q(m) increases ↑, and the force of the main flow Q(m) on the disc increases too. The valve disc of the main road moves upward under the force of the main road flow, the bypass will become slightly smaller, and the main road will be slightly larger.

- If P1 continues to increase ↑, the main flow Q(m) continues to increase ↑, and the pressure of the main flow on the disc also increases accordingly. The valve disc continues to move upward under the force of the main flow. When Q(m) >Q(min), The force of the main flow on the disc is bigger than the force of the spring. At this time, the bypass is completely closed, while the main flow is fully opened.

The automatic recirculation valve is to realize the opening and closing of the disc in the continuous change of the main flow rate, and at the same time realizes the closing and opening of the bypass through the connecting rod.

The key component

The operation of the valve is closely related to the components, below three components are the most important.

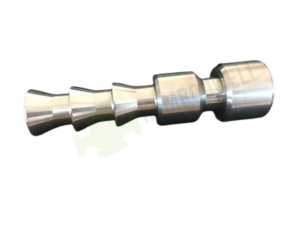

1, Disc

- The main flow disc is calculated and processed to obtain a specially processed surface.

- It can sense the change in flow rate.

- It is machined by CNC

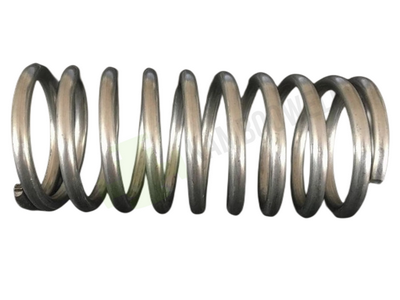

2, Spring

- The springs are made by high strength spring steel.

- The spring can withstand 100000 times compression without fatigue deformation.

3,Bypass

Bypass design is a key component in reducing the pressure to the required value.